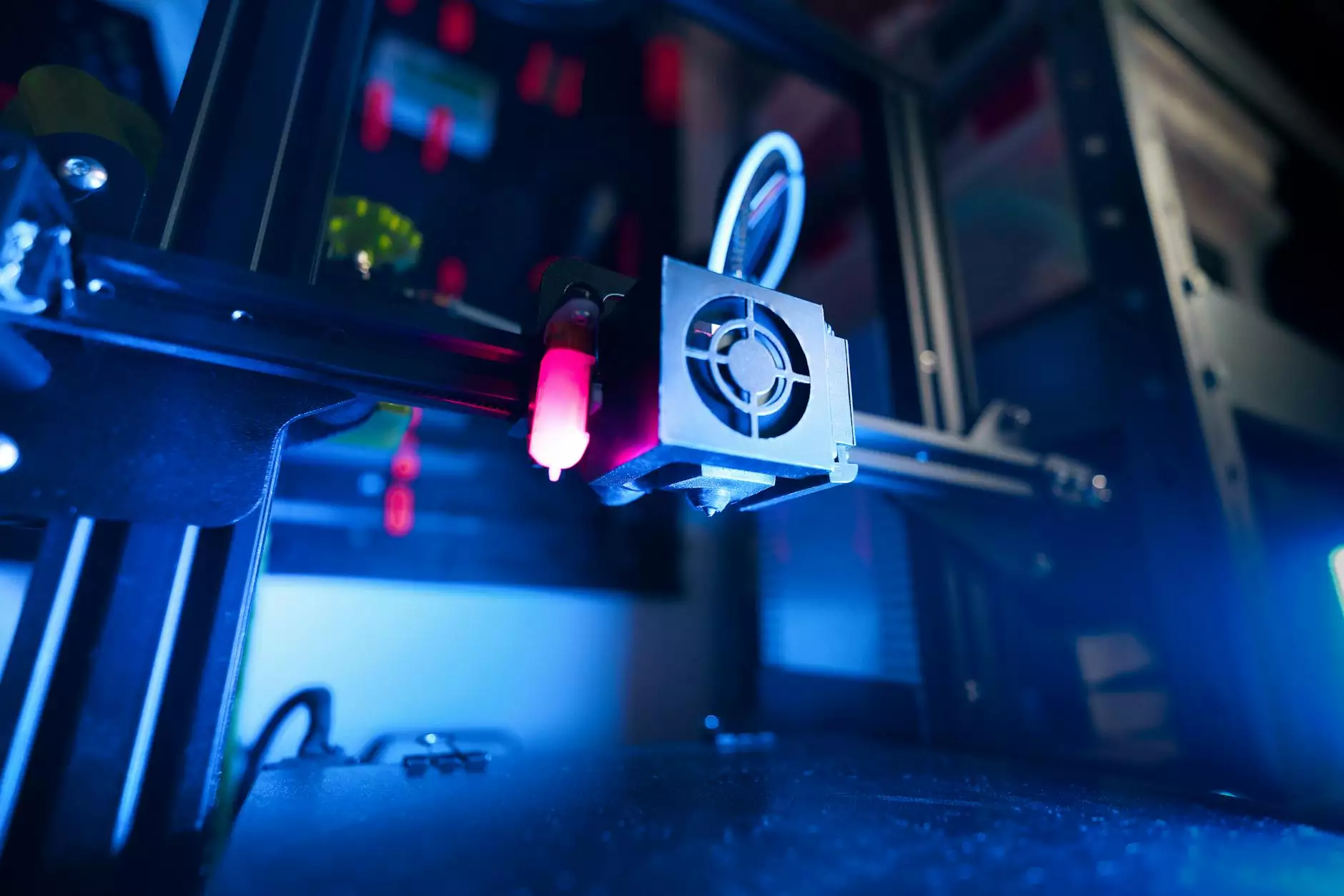

The Power of Industrial Laser Cleaning Machines for Metal Fabricators

As technology continues to evolve at a rapid pace, the field of metal fabrication is no exception. In today's competitive landscape, efficiency and precision are key factors for success. This is where industrial laser cleaning machines come into play, offering a revolutionary solution for Metal Fabricators at dplaser.com.

Unleashing the Potential of Laser Cleaning Technology

Industrial laser cleaning machines utilize the power of laser beams to effectively remove contaminants, oxides, coatings, and other unwanted substances from metal surfaces. Unlike traditional cleaning methods that involve chemicals or abrasive materials, laser cleaning provides a non-contact, environmentally friendly, and highly efficient solution.

Key Benefits of Industrial Laser Cleaning Machines

- Precision: Laser cleaning allows for precise targeting of specific areas, ensuring thorough cleaning without affecting the surrounding surfaces.

- Efficiency: With rapid cleaning speeds and minimal setup time, industrial laser cleaning machines streamline the cleaning process, saving valuable time and resources.

- Cost-Effectiveness: By eliminating the need for consumables and reducing manual labor, laser cleaning offers a cost-effective solution for Metal Fabricators at dplaser.com.

- Safety: Laser cleaning minimizes the risk of operator exposure to hazardous chemicals and reduces the generation of waste, promoting a safer working environment.

- Versatility: From rust removal and paint stripping to surface preparation and weld cleaning, industrial laser cleaning machines can handle a wide range of applications with precision and consistency.

Applications of Industrial Laser Cleaning Machines in Metal Fabrication

The versatility of industrial laser cleaning machines makes them indispensable tools in various metal fabrication processes. Metal Fabricators at dplaser.com can leverage the capabilities of laser cleaning for:

- Surface Preparation: Laser cleaning ensures optimal surface conditions for welding, painting, and coating applications, enhancing adhesion and quality.

- Rust and Corrosion Removal: By selectively removing rust and corrosion without damaging the base material, laser cleaning extends the lifespan of metal components.

- Coating Removal: Efficiently stripping old coatings from metal surfaces, laser cleaning facilitates quick recoating and refurbishment processes.

- Weld Cleaning: Laser cleaning effectively removes contaminants, spatter, and oxides from weld joints, ensuring clean and strong welds.

Embracing Innovation for Enhanced Productivity

With the rapid advancements in laser technology, industrial laser cleaning machines continue to evolve, offering Metal Fabricators at dplaser.com cutting-edge solutions for improving productivity, quality, and sustainability. By integrating laser cleaning into their processes, businesses can gain a competitive edge in the market and meet the demands of modern manufacturing standards.

Conclusion

Industrial laser cleaning machines represent a paradigm shift in metal fabrication, revolutionizing the way Metal Fabricators at dplaser.com approach cleaning and surface treatment processes. With their precision, efficiency, and versatility, these advanced tools empower businesses to achieve higher productivity, reduce costs, and deliver superior quality products. Embrace the power of industrial laser cleaning machines and experience the transformative impact on your business.